Sustainability

Red Stag TimberLab is reducing the dependence on non-renewable resources that produce materials such as steel and concrete by converting logs into attractive and efficient major structural elements.

Plantation forests cover 2.1 million hectares of New Zealand land area. They provide a healthy oxygen-filled environment for many leisure activities.

Because they are harvested on a renewable basis, they also provide vast quantities; some 20 million cubic metres of high-quality material each year.

Glulam

New Zealand’s Most Sustainable Building Material

Building and construction is one of the sectors causing the most significant depletion of the earth’s natural resources.

Concrete and steel have been the dominant building materials throughout the 20th Century, but manufacturing these materials contributes significantly to Green House Gas emissions.

Carbon Sequestration

Trees absorb carbon dioxide as they grow through the process of photosynthesis. This carbon is commonly referred to as embodied carbon. Over the long term, the embodied carbon will return to the atmosphere and complete the natural carbon cycle, but the temporary CO2 wood storage can be reasonably taken as a carbon credit. Trees remove and store around 1.8kg CO2 / kg wood from the atmosphere during growth. Each m3 of solid Pinus Radiata glulam therefore stores approximately 900kg of CO2.

The table below provides an estimate of embodied carbon (kg CO2-eq) of an equivalent concrete, steel, and timber beam (data sourced from the New Zealand Wood Design Guides). For the structure assessed, the timber beam absorbs 16kg CO2-eq, whilst the equivalent steel beam emits 45kg CO2-eq.

Carbon Emissions of Equivalent

Steel / Concrete / Timber Beams

Glulam timber also has a high strength-to-weight ratio and is a light-weight alternative to concrete or steel construction.

A low mass Glulam structure requires less bracing, and the gravity loading on the foundations is substantially reduced. The net result is reduced foundation costs (especially where soils are weak), and less truck deliveries required to site – both of which significantly reduce carbon emissions.

Living Building Challenge

Contributing to the achievement of the high standards of the Living Building Challenge, Red Stag TimberLab’s FSC Certified Glulam products form the main structural system for this first in New Zealand Living Building – Tūhoe’s Te Kura Whare.

Living Building Challenge

EPD Certification

FSC Certification

Red Stag TimberLab holds Chain of Custody Certification Code NC-COC-005630 for the supply of FSC® certified timber. Material is sourced from renewable NZ Radiata plantation forests that are sustainably managed and recognised as contributing environmental benefits as opposed to steel and concrete and scarce rain forest hardwoods.

With FSC certification, we have the proof that our raw materials are obtained from sustainably managed forests, that sourcing of the raw materials is internally monitored and that conditions connected to external monitoring by third parties are fulfilled.

In 2019 TimberLab, as participants with the Wood Products and Manufacturing Association (WPMA) released an EPD for timber products made in New Zealand from Radiata Pine. This assesses environmental impact, resource use, and waste output across 27 different environmental impact criteria.

The full assessment report can be downloaded here.

The Living Building Challenge (LBC) is the most advanced sustainability accreditation program currently available in our built environment. LBC has the philosophy to encourage project stakeholders to develop building assets which have a “truly regenerative” impact on the environment.

LBC is made up of 20 imperatives grouped into 7 different “Petals”. Red Stag TimberLab Glulam is associated with the “Materials Petal” (Petal 5) which aims to create a materials economy which is non-toxic, ecologically restorative, and transparent.

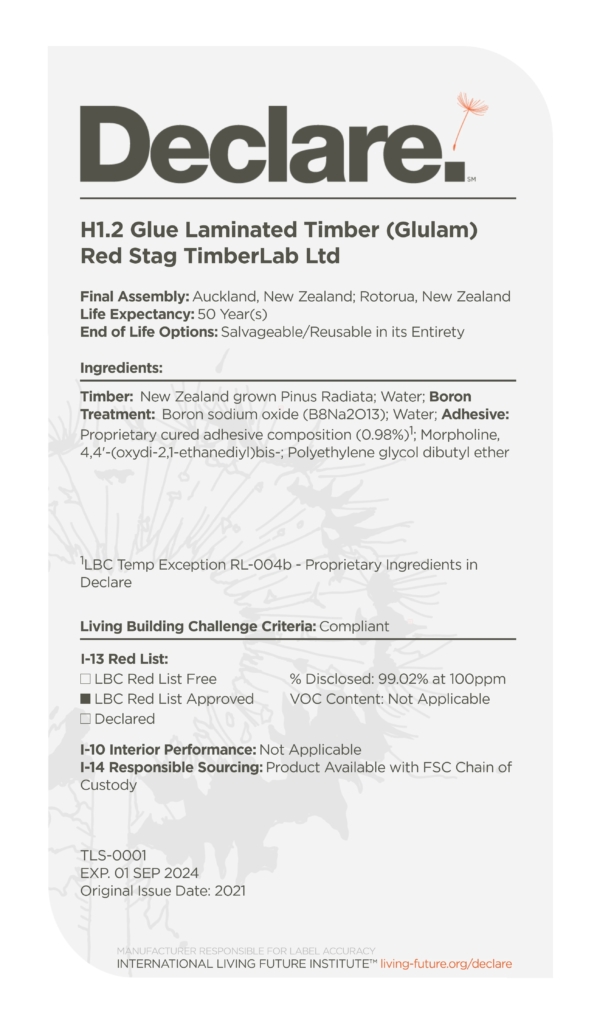

Declare certification is a transparency tool created to support the LBC to declare all chemical components within products. Declare is essentially a “nutrition label” for products which becomes part of a publicly accessible database of building materials.

Red Stag TimberLab is proud to have received Declare certification (Living Building Challenge Red List Approved) for 2 products; H1.2 Glulam for interior use, and H3.2 MCA Glulam for exterior use.

Wood is, by far, the world’s most sustainable building material. Sustainable forestry practices and certification in New Zealand means that vast quantities of timber can be used in construction materials to create long-term carbon sinks, which continue to grow day-by-day. Instead of sending this material overseas as low value logs, TimberLab is committed to producing value-added timber solutions in the way of engineered timber structures as an environmental alternative to concrete and steel.

Red Stag TimberLab Laboratory Testing for VOC (Volatile Organic Compounds)

Awareness of sustainability in our built environment is becoming a key factor in procurement decisions for building materials. Internationally recognised certifications such as Green Building and Living Building are becoming a popular way to measure and monitor the environmental impact of new buildings.

Volatile Organic Compounds – Formaldehyde

Formaldehyde is found in every living system – all wood species, and therefore all wood products contain and emit small amounts of formaldehyde. At high levels of exposure, formaldehyde is a known carcinogen but in small concentrations, formaldehyde is not known to cause adverse health effects. It metabolizes quickly so does not accumulate in the body.

VOCs, including formaldehyde are key factors relating to the discomfort reported by people working or living inside “air-tight” buildings. VOCs and specifically formaldehyde are of interest in Engineered Wood Products containing adhesives, which can be associated with emissions.

To satisfy certification requirements, credit is available where all engineered wood products used in a project have no or low formaldehyde levels according to stipulated formaldehyde limits.

Red Stag TimberLab has recently undertaken formaldehyde emission testing on a range of Red Stag TimberLab Glulam and LVL products to satisfy requirements for Indoor Pollutants. Formaldehyde emission testing was carried out in accordance with AS/NZS 4357.4.

Formaldehyde Test Results

Certification Performance Categories

Formaldehyde Test Results

Seven Glulam and LVL products were tested for formaldehyde emissions. The tested samples contained different laminate thicknesses, different treatment levels, and different adhesive types.

H1.2 emissions were similar to H3.2 and H5 showed slightly elevated emissions.

Laminate thickness – Thinner laminates resulted in higher emissions.

All tests showed very low levels of emitted formaldehyde; the maximum emission being 0.27 mg/L. To meet Green Star requirements, test results must be less than 1 mg/L (under AS/NZS 4357.4 test protocol) which is almost 4 times greater than the highest test result recorded from Red Stag TimberLab products. All test results for Red Stag TimberLab products passed even the most stringent Super E0 emission level, set at 0.3 mg/L.

It can therefore be concluded that Red Stag TimberLab Glulam and LVL products have a negligible impact on indoor air quality.

Recyclability and Waste

Because all of Red Stag TimberLab’s components are modelled in 3D, and CNC profiled to exact dimension and shape, there is no oversupply of materials to the building site. The environmental cost associated with transporting excess material to the site and then carting it away again for disposal is eliminated.

In New Zealand, the most common end-of-life method is landfill. Recycling is of huge significance when considering whole-of-life carbon cost. When a timber product is recycled into a new building, the carbon sequestration can remain intact at end-of-life.

Because most of the connection details in mass timber construction are simple screw or bolted fixings, at the end of the building’s life the timber elements can be simply unfixed, re-machined if necessary and used in a new building.

These recycled materials can replace alternative materials with potentially high carbon emissions. The circular economy approach to sustainable construction is becoming popular when designers choose building materials and connection details. In a circular economy, resources are kept in use for as long as possible to extract the maximum value from them.

Recyclability and Waste

Because all of TimberLab’s components are modelled in 3D, and CNC profiled to exact dimension and shape, there is no oversupply of materials to the building site. The environmental cost associated with transporting excess material to the site and then carting it away again for disposal is eliminated.

In New Zealand, the most common end-of-life method is landfill. Recycling is of huge significance when considering whole-of-life carbon cost. When a timber product is recycled into a new building, the carbon sequestration can remain intact at end-of-life.

Because most of the connection details in mass timber construction are simple screw or bolted fixings, at the end of the building’s life the timber elements can be simply unfixed, re-machined if necessary and used in a new building.

These recycled materials can replace alternative materials with potentially high carbon emissions. The circular economy approach to sustainable construction is becoming popular when designers choose building materials and connection details. In a circular economy, resources are kept in use for as long as possible to extract the maximum value from them.

Health and Wellness

The biophilia hypothesis suggests that humans possess an innate tendency to seek connection with nature and other forms of life. The improvements in health and happiness that are associated with spending time outside in nature are well known. Exposure to nature has been shown to lower blood pressure, heart rate, and aggression. Nature also increases the ability to focus attention and perform concentration and creative tasks.

Mass Timber also acts as a natural humidity buffer to make for a healthy in-built environment; absorbing atmospheric moisture when it is wet and releasing it again when it is dry. You will not see interstitial condensation on timber joinery, and the same goes for glulam beams or columns forming part of the building envelope.

Sustainability is now established as a fundamental requirement for modern construction. There is universal acceptance that conservation of the Earth’s resources is essential to our survival and our regulatory framework is rapidly adapting to meet this requirement. In 2019, the New Zealand Government passed the ‘Zero Carbon’ Bill, committing the country to reducing net emissions of all greenhouse gases to zero by 2050. Being responsible for approximately 16% of total Greenhouse Gas emissions, the construction industry has a big part to play in achieving Government’s goal.