Credit: Illustration by www.stantiallstudio.co.nz

Project Credits

Client: Te Herenga Waka – Victoria University of Wellington | Builder: LT McGuinness | Architect: Tennent Brown Architects | Structural Engineer: Dunning Thornton Consultants | Product: CLT & Glulam

Tōia mai rā ngā waka i te au a Tāne ki ngā waikarekare, pareārohirohi o Te Whanganui a Tara. Kia ū ki te take o Ahumairangi.

Orokotomo mai i Te Apa Māreikura o Māui ki ngā pari karangaranga o Rongomaraeroa ki Te Tumu Herenga Waka. Te pātaka kai iringa o te kupu o te kōrero.

He pā mataora. Ka takina te kawa a Te Rangiahuta. E tū e hine mā, e tama mā whakaarahia ake ngā poupou o tō whare o Te Herenga Waka.

He pā kaiao. Ka takina Te Kawa a Māui, te iho o te whakaaro i ahumainuku, I Ahumairangi.

Ko Te Poukairangi te pae kia eke. He pā anamata.

Tīhei mauri ora!

Drag forth the canoes across the rippling and quivering waves of Wellington harbour until you reach the base of Ahumairangi.

Enter through the carved gateway named Te Apa Mareikura o Maui to the reverberating domain of Rongomaraeroa to the carved meeting house, Te Tumu Herenga Waka. The storehouse of words and knowledge.

A thriving community – where the teachings of Te Rangiahuta continue to remind us to stand up, one and all, and maintain the posts of your house, Te Herenga Waka.

A living lab – where the teaching of Maui inspire and extend our understanding that emanate from the eart and from the sky.

Where the Poukairangi becomes the standard to aspire and to ensure a sustainable future.

And so it begins.

The above text is taken from The Living Pa Booklet published by Te Herenga Waka – Victoria University of Wellington (2018) and served as an inspiration to Red Stag TimberLab (RSTL) throughout this project.

When embarking on the Living Pā journey, Red Stag TimberLab took the above inspiration to adopt a “can do” attitude to the ambitious and innovative design which involved:

- Innovation – specific R&D prototype testing on new composite sections.

- Digital fabrication and Prefabrication – as much as possible to optimize installation speed.

- Environmental Certification – to comply with stringent Living Building Challenge requirements.

Living Pā Overview

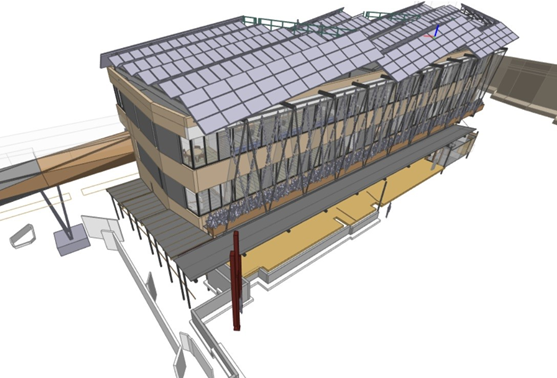

Red Stag TimberLab, New Zealand’s leading supplier of mass timber solutions, played a pivotal role in the Living Pā project. The project involves the redevelopment of a pan-tribal, university-based marae, incorporating a new 3000m2 mid-rise structure alongside the existing wharenui. This expansion aims to enhance marae engagement and teaching spaces while embodying Māori values and achieving stringent sustainability certification under the Living Building Challenge.

In particular, the design parameters for CLT pushed the known boundaries of capability and manufacture, and Red Stag TimberLab is proud to have worked with all stakeholders to achieve spectacular results.

Innovation

Red Stag TimberLab supplied several Engineered Wood Products to the Living Pā project. CLT panels, GLT beams, and composite sections were used for various structural elements including floors, roofs, beams, columns, stairs, and lift shaft walls.

The project includes many innovative sections and structural elements such as CLT-GLT composite T-beams, CLT-LVL reverse T-beams, and CLT-GLT box beams to support large-span CLT floors. The use of CLT-Glulam box beams is particularly noteworthy, facilitating expansive open spaces within the building. These beams, spanning nearly 9 metres, are essential for supporting significant loads. The structure is designed to carry large combinations of imposed and dead load for educational use.

Full-Scale Prototype Testing

Due to the novelty of the design and complex structural system, Red Stag TimberLab carried out full-scale testing on the CLT-GLT composite beams to ensure structural performance aligned with the engineer’s design parameters. Sustained load was applied to the elements for more than 3 months in Red Stag TimberLab’s factory to assess the long-term structural performance of the beams aligned with the design criteria.

Full-scale CLT-GLT composite T-beams tested by Red Stag TimberLab

Digital Fabrication & Prefabrication - to optimize speed onsite

Digital Fabrication

Red Stag TimberLab was selected for its expertise in providing sustainable timber solutions and digital modelling capabilities. Red Stag TimberLab utilized its advanced digital fabrication technologies to design and manufacture CLT and Glulam components tailored to the specific structural requirements, ensuring high precision and quality.

The accurate CNC digital fabrication process, and the timely delivery of products to the building site facilitated smooth coordination, and a rapid assembly process.

Prefabrication

The lightweight properties of mass timber allow for easy transportation and machining, making offsite prefabrication an attractive option. This prefabrication approach significantly speeds up the construction process. For example, the CLT composite panels were prefabricated into 7.2 x 3.0m sections at Red Stag TimberLab’s Rotorua factory. These panels are then quickly installed on-site, providing immediate usable floor spaces without temporary propping. This presents a major improvement over conventional concrete floor construction, which typically requires extensive propping and several days to set.

Reverse T units being craned into position.

Red Stag TimberLab CLT lift shaft panels were utilized in the project to assist with the rapid installation programme. CLT lift shafts can be erected faster and easier than similar steel and concrete alternatives while providing exceptional lateral bracing for the building. Elevator and stair shafts can comfortably achieve a one-hour fire resistance rating when using a 126 mm thick (or greater) three-layer Red Stag TimberLab CLT panel.

CLT shear walls being rapidly installed.

The design also includes the integration of large Glulam planters on the building’s second floor which were CNC fabricated for all penetrations and connection details. These planters, suspended from steel tubes at the roof level and braced by CLT spandrels, not only connect the structure to the surrounding natural environment but also demonstrate Glulam’s versatility and aesthetic appeal.

Prefabricated Glulam planter units being craned into position.

Sustainability

Living Building Challenge

The Living Building Challenge (LBC) represents the most advanced sustainability accreditation program currently present in our built environment. It promotes developments that have a “truly regenerative” impact on the environment. The stringent green building guidelines necessitate net-zero energy and water, as well as strict waste and toxicity limits for all building components. Unlike other certifications that seek to minimize negative environmental impacts, the LBC promotes a philosophy of positive outcomes. A Living Building should have a positive impact on the environment, its inhabitants, and the broader ecosystem. In other words, the world should be in a better state after the development than it was previously.

The Living Pā is aiming to achieve Living Building Certification which will be assessed and granted after the building has been operational for a 12-month period to prove performance in terms of energy and water use.

Environmental Certification

To be considered as a key supplier for a Living Building project, Red Stag TimberLab has achieved the following environmental credentials:

FSC Certification

Red Stag TimberLab holds Chain of Custody Certification Code NC-COC-005630 for the supply of FSC® certified timber. Material is sourced from renewable NZ Radiata plantation forests that are sustainably managed and recognised as contributing environmental benefits as opposed to steel and concrete and scarce rain forest hardwoods.

With FSC certification, we have the proof that our raw materials are obtained from sustainably managed forests, that sourcing of the raw materials is internally monitored and that conditions connected to external monitoring by third parties are fulfilled.

Declare Certification

The Living Building Challenge is made up of 20 imperatives grouped into 7 different “Petals”. Red Stag TimberLab CLT and Glulam is associated with the “Materials Petal” (Petal 5) which aims to create a materials economy which is non-toxic, ecologically restorative, and transparent.

Declare certification is a transparency tool created to support the LBC to declare all chemical components within products. Declare is essentially a “nutrition label” for products which becomes part of a publicly accessible database of building materials. Red Stag TimberLab is proud to have received Declare certification (Living Building Challenge Red List Approved) for; H1.2 Glulam for interior use and H3.2 MCA Glulam for exterior use.

Environmental Product Declaration (EPD)

An Environmental Product Declaration (EPD) is a robust, science based, independently verified and standardized method for communicating the environmental impacts of products. Red Stag TimberLab’s EPD’s are based on a cradle-to-gate Life Cycle Assessment (LCA), with end-of-life options included. ‘Cradle’ refers to the raw material extraction and ‘the gate’ is the boundary of the manufacturing factory as the product is being dispatched to customers.

Red Stag Timber has become a market leader in terms of product innovation and manufacturing capacity. The company has been recognised as a leader in New Zealand for contribution to Energy Efficiency and Conservation in New Zealand by receiving the 2018 EECA award for Large Energy User of the Year.

Bio-Fuel Energy

Red Stag Timber utilises offcuts from sawing and planing as a bio-fuel to generate electricity and provide thermal energy to dry timber. Red Stag Timber is also a net exporter of electricity to the national grid to help power New Zealand’s growing energy needs.

Thermal Energy

Wood waste is used as the energy source for the kiln drying of timber. The thermal energy required to kiln dry timber can exceed 85% of the energy usage for a modern sawmill. Utilising its own wood offcuts as an energy source ensures that both CO2 emissions and landfill disposal requirements are minimised.

Carbon Sequestration

The Living Pā project, spanning four levels, required a total volume of 1131m³ of Engineered Wood Products (EWP). This included Red Stag TimberLab’s supply of 858 m³ of Cross Laminated Timber (CLT) and 115 m³ of Glue Laminated Timber (GLT).

The Living Pā project showcases the significant positive environmental effect of replacing steel and concrete elements with EWPs. Red Stag TimberLab’s contribution to the project (858m3 of CLT and 115m3 of GLT) has an estimated carbon sequestration of 687 tonnes of CO2eq.

Quality Control

Red Stag TimberLab Ltd is a licensed manufacturer, independently audited under AS/NZS 1328.1 for glulam manufacturing (License No. 2916) and AS5068 for finger jointing (License No. 2915).

Regular in-factory quality control is carried out in conformance with these, third-party auditing carried out by Bureau Veritas.

Testimonial

“The Living Pā has been a challenging project and we have been very pleased to partner with Red Stag TimberLab for the delivery of the CLT and GLT components of the mass timber superstructure. The project has had many firsts for the whole team and Red Stag’s willingness to solve problems and adapt their production for the complex array of prefabricated parts has been one of the project highlights. The smoothness of the erection of the superstructure on site is a testament to this.”

— James McLean – L.T. McGuinness Project Manager for the Living Pā

Contact the Red Stag TimberLab team to discuss how you can include mass timber in your upcoming project.

Or

Email: info@redstag.co.nz

Phone: 09 253 9349

Stay informed on Red Stag TimberLab’s project progresses, technological advancements and industry news by subscribing to our monthly newsletter.