Project Overview

The Westin Boathouse project required a structurally expressive, architecturally refined timber solution that would celebrate its waterfront setting while meeting modern performance, sustainability, and durability expectations. A key feature of the design was its sweeping roof form and ribbed structural shell, elements that relied heavily on the precision and capability of advanced timber engineering. The project team sought a partner who could deliver large-scale curved Glulam elements with tight tolerances, consistent quality, and confidence in on-site buildability in Fiji.

Red Stag TimberLab's Involvement

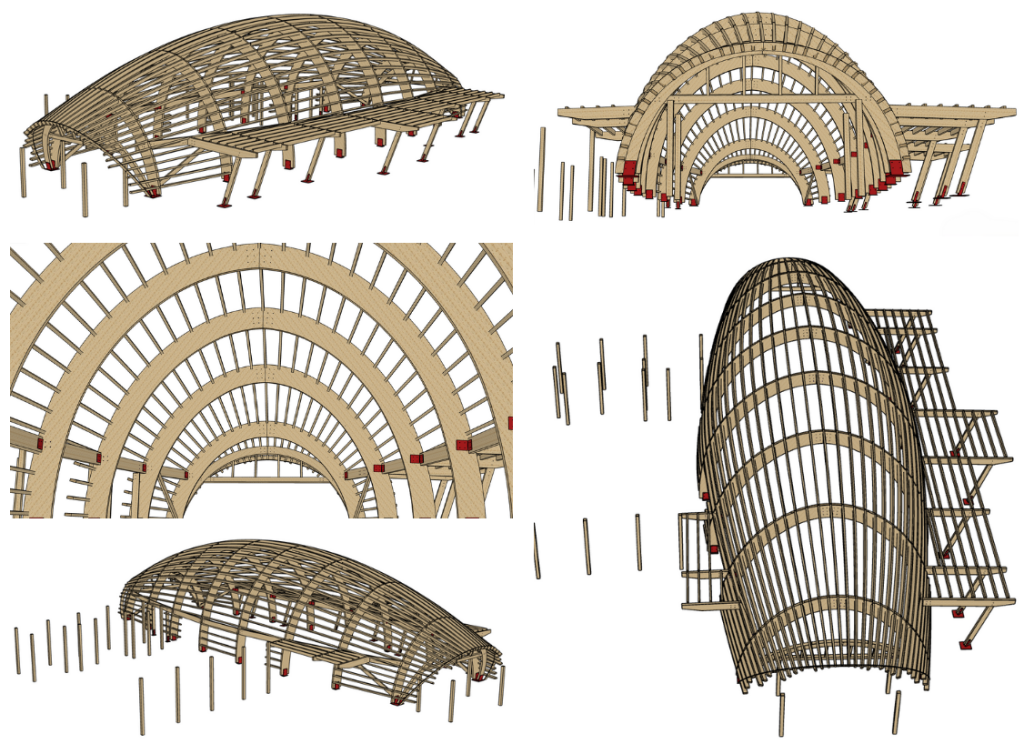

Red Stag TimberLab (RSTL) supplied all Glulam structural members for the Westin Boathouse, including the signature curved arches that define the building’s architectural identity. These members were manufactured with millimetre-level precision to achieve the complex geometry of the long-span arching framework and the intersecting ribbed structure.

RSTL’s fabrication process ensured each curved element was delivered as an accurately profiled, pre-assembled component, streamlining installation and significantly reducing on-site risk and time. The large Glulam arches act as the primary load-bearing system, providing long-span capability while maintaining a lightweight, low-carbon structural palette.

Digital Fabrication

The project’s demanding geometry required an advanced digital workflow from early coordination through to final fabrication. RSTL used:

- 3D modelling and analysis to verify curvature, intersection angles, and alignment between members.

- CNC machining to achieve tight tolerances and ensure seamless assembly.

- Pre-assembly checks to confirm accuracy before delivery to Fiji.

This digital approach reduced construction waste and allowed the complex forms to be built efficiently and safely on site.

Sustainability and Renewable Energy

As New Zealand’s lowest-carbon engineered timber supplier, Red Stag TimberLab contributed significant environmental value to the project.

Material statistics:

- Net Glulam volume: 62 m³

- Weight: 32.1 tonnes

- Net carbon impact: -40 tonnes CO₂e

By utilising Glulam instead of heavier steel alternatives, the project reduced environmental impacts, improved transportation efficiency, and supported a renewable, high-performance building solution. RSTL’s production is powered by Red Stag Timber renewable energy, using wood-waste biofuel for thermal and electrical energy, further reducing the carbon footprint of the supplied materials.

Results

Red Stag TimberLab’s precision-engineered Glulam enabled the creation of an iconic structural form that is both expressive and high performing. The flowing curvature of the arches and ribbed shell demonstrates how mass timber can unlock complex, sculptural architecture while delivering a:

- Durable solution in a coastal environment.

- Lightweight construction suited to remote or constrained sites.

- Faster and more predictable installation

- Reduced carbon footprint.

- Highly architectural solution.

The Westin Boathouse stands as a testament to how engineered timber, supported by advanced digital fabrication, can elevate both the architectural and structural ambitions of a project.

Project Credits

Project: Inu Oki Lima Boathouse Restaurant (The Westin)

Architect: Conway Architects

Engineer: Permal Consultants

Construction: Fletcher Building (Fiji)

Product: Curved and Straight Glulam

Contact the Red Stag TimberLab team to discuss how you can include mass timber in your upcoming project.

Or

Email: info@redstag.co.nz

Phone: 09 253 9349

Stay informed on Red Stag TimberLab’s project progresses, technological advancements and industry news by subscribing to our monthly newsletter.